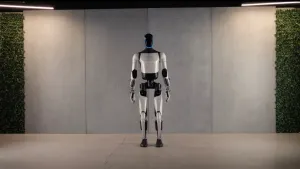

Millions of humanoid robots, those that look and move like humans, could become regular fixtures in factories and homes, bringing down manufacturing costs, eliminating dreary and dangerous work, and launching humanity into an age of abundance, according to the CEOs of Tesla and Figure AI. Both companies have humanoid prototypes that look amazingly lifelike and are trained using artificial intelligence.

Here’s a head-to-head comparison of these humanoid robots and a summary of what their CEOs expect in the future:

(1) Adcock’s vision

Brett Adcock, CEO of Figure AI, has a plan. The company has built 10 humanoid robots, and it’s building one additional robot a week. A planned production line in California should produce hundreds of robots next year; shortly thereafter, thousands of robots will be manufactured annually.

At first, robots will be used in factories, filling vacant jobs, and doing work that isn’t desirable or dangerous, Adcock said in an August 22 podcast. Within the next three years, humanoid robots will also work in homes, doing chores, running errands, and even walking the dog. Figure AI’s humanoids won’t be on the battlefield because the company doesn’t do defense-related work, he said. He believes there’s plenty of opportunity in the civilian market, where he forecasts 3 billion to 5 billion robots will be in the workforce by 2040. At some point, Adcock believes, everyone will own a humanoid.

As manufacturing ramps up, the cost of producing a humanoid robot should fall below $20,000. And ultimately, when robots build robots in factories powered by renewable energy, the price tag should fall much further. Adcock also envisions owners generating income by leasing or renting their robots to others when they’re not in use.

Companies will buy humanoid robots because they can be added to manufacturing lines without changing the layout of the factory floor or bringing in additional new equipment. Powered by artificial intelligence, humanoid robots will be trained easily through verbal commands or physical demonstration. And as one robot gets trained, its “knowledge” can be instantly shared with a fleet of robots. At first, humanoid robots will work in areas separated from humans. But within this decade, they’ll be working alongside humans. Here’s a video of Figure 2.0 working on a BMW assembly line in South Carolina during a trial run earlier this year.